High Quality Wafer End Connection Butterfly Valve

Production Description

●The connection between the disc plate and the valve body adopts a pin-free structure, which overcomes the possible internal leakage point.

●The outer circle of the butterfly plate adopts spherical shape, which improves the sealing performance and prolongs the service life of the valve.

●The outer surface of the valve body is electrostatically sprayed with epoxy resin, and the disc plate can be sprayed with coating according to user requirements, such as nylon or F46.

●Reliable sealing performance. Precise casting process and precise size, select NBR with excellent physical and mechanical properties and processing performance as sealing material, stable operation and reliable sealing performance

●Combination of high-quality materials. The sealing material is made of stainless steel and nitrile oil-resistant rubber, which is wear-resistant and corrosion-resistant and has a longer service life.

●The angle can be fixed arbitrarily. It can be fixed arbitrarily within a range of 90°. The valve has a bidirectional sealing function. It is not affected by the control of the medium flow and the spatial position during installation. It can be installed in any direction, and the operation is flexible, labor-saving and convenient.

●Painted to prevent rust. The overall baking paint can effectively prevent rust and can be used for different media.

●QT450 ductile iron valve body. The selection of ductile iron as the valve body material has excellent casting, machining and wear resistance, and has a certain elasticity

●304 stainless steel valve plate. Corrosion resistance, impact resistance, long service life

●EPDM base seal. Acid and alkali resistance, detergents, animal and vegetable oils, alcohols and ketones, etc., the highest temperature can reach 120 °C, and it has excellent chemical resistance

●Ductile iron turbine head. Ductile iron is selected as the valve body material, which has excellent casting, cutting and wear resistance, and has a certain elasticity

Application Area

Installed in water supply and drainage, sewage, food, gas, shipbuilding, hydropower, metallurgy, energy system and light textile industries, especially suitable for two-way sealing and valve body prone to corrosion. The valve is a conventional butterfly valve that is preferred for pipelines. It has the advantages of post-section, simple structure, small flow resistance coefficient, and the flow characteristics tend to be straight, and no debris will be retained. It can be used to cut off the medium and adjust the flow of the medium.

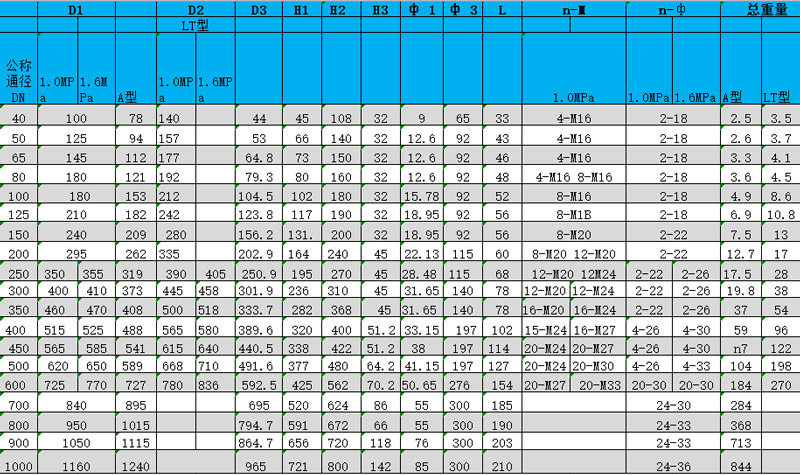

Product Specifications

Product Display