How great is a smart factory with no one watching the “pipe“?

(Reprint netease News)

There is a “miracle” that attracts the world’s attention, called China’s speed. The rapid development of China’s construction is a vivid portrayal of China’s speed. Behind China’s construction is the strong support of Made in China and the great step forward of scientific and technological innovation.

China’s construction, related to the national economy and people’s livelihood, cannot be separated from the bearing of pipelines. Energy transmission, power communication, urban drainage system and other livelihood projects are inseparable from the transportation of pipelines. The fast speed of China’s construction also enables the pipeline manufacturing industry to accelerate innovation, improve the quality and efficiency.

So, how does the pipeline industry keep up with the pace of national development? Reveals how China Pipeline Smart Factory interprets “Great Made in China”.

What does a 24-hour non-stop unmanned workshop look like?

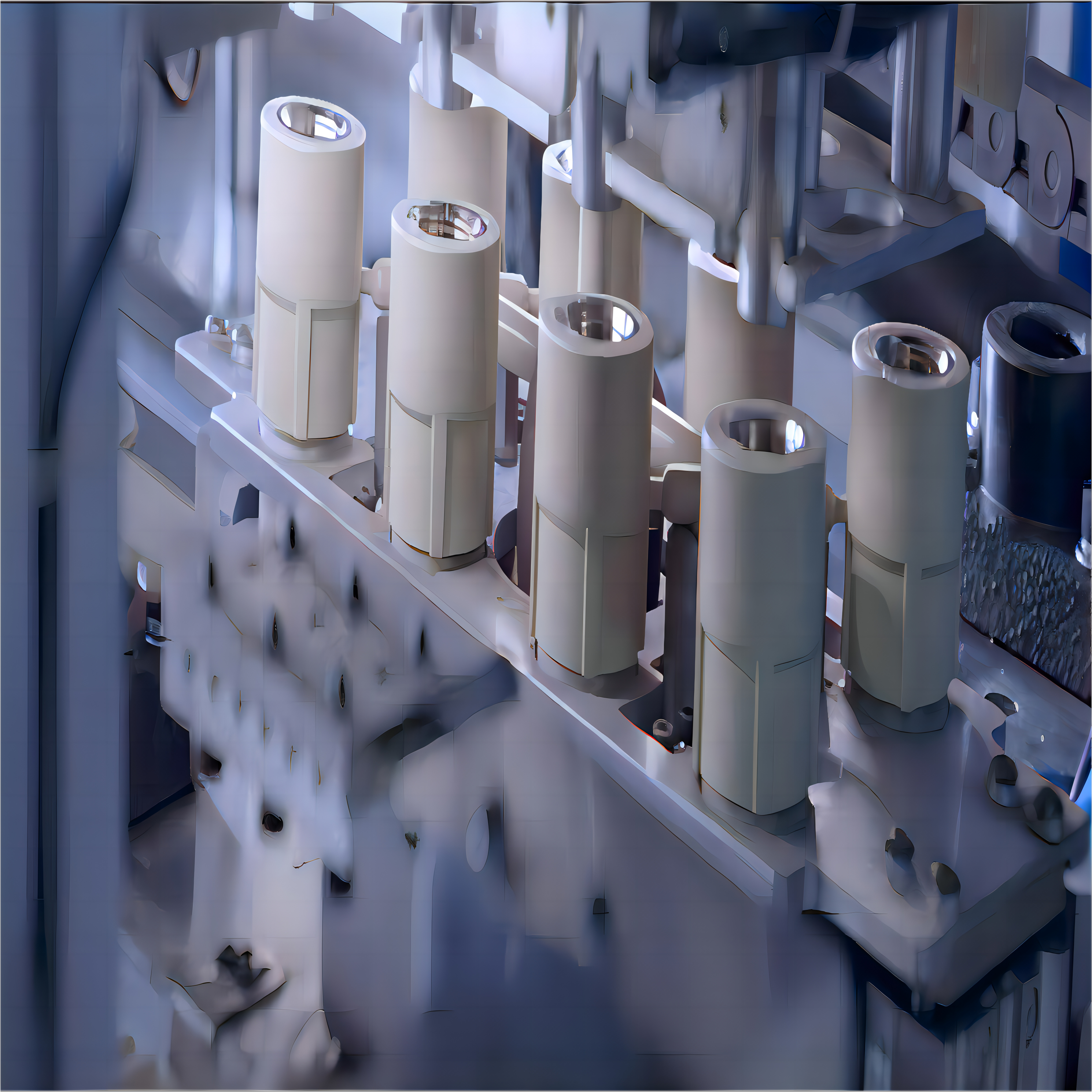

In many people’s impression, the pipeline belongs to the common building materials, its production process from raw material processing to extrusion, packaging all links are inseparable from people. In the intelligent factory of China pipeline, the automation has been launched since the beginning of the mixing, and the pipeline has realized the intelligent automation of the production, packaging and warehousing of pipe fittings, which people rarely see in the workshop.

The unmanned workshop operates 24 hours a day, and the interaction between each process is coordinated by the system, without manual intervention, to achieve automatic production. Under the control of the intelligent system, the automatic batching, feeding and injection molding are realized, and the automatic shear water inlet is realized in the mold, and then the product and water inlet are removed by the manipulator, and put by classification.

“In this smart pipe fitting workshop, each device can produce 1.82 products in 24 seconds, and 41 devices can operate all day long, greatly improving the production efficiency. The qualified rate of the automatic production line is as high as 99.8%.”

The automatic packaging line of the intelligent workshop also deployed the anti-counterfeiting coding system, the automatic laser coding provides an identity authentication information for each product, consumers can buy the plastic pipeline, can scan the security code on the pipeline, trace the production information and authenticity of the product.

With the improvement of automation, the plant reduces the allocation of personnel and optimizes the resource allocation, reducing energy consumption and improving the comprehensive utilization rate. From traditional manufacturing to intelligent manufacturing, China Union Plastic has been greatly improved in its production capacity, quality, control, resource coordination and other aspects.

Post time: Nov-08-2022