HDPE Steel Belt Reinforced Spiral Corrugated Pipe

Production Description

Application Area

Municipal field

municipal drainage, sewage

Construction field

building drainage, underground drainage, sewage, building ventilation, etc.

Agricultural field

farmland, orchard, vegetable garden and forest belt irrigation and drainage, etc.

Industrial field: sewage and wastewater discharge in chemical, pharmaceutical, environmental protection and other industries

Transportation field: water seepage and drainage of railways and expressways

Water conservancy field: well wall pipe for well sinking engineering

Other fields: water seepage and drainage in golf courses, football fields and other industries

Product Specifications

|

Specifications |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

|

Minimum internal diameter |

294 |

392 |

490 |

588 |

673 |

785 |

885 |

985 |

1085 |

|

Maximum outside diameter |

332 |

450 |

558 |

670 |

780 |

885 |

997 |

1110 |

1221 |

|

Specifications |

1200 |

1300 |

1400 |

1500 |

1600 |

1800 |

2000 |

2200 |

|

|

Minimum internal diameter |

1185 |

1285 |

1385 |

1485 |

1585 |

1785 |

1985 |

2185 |

|

|

Maximum outside diameter |

1325 |

1421 |

1530 |

1665 |

1740 |

1960 |

2207 |

2396 |

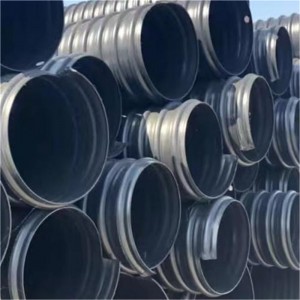

Product Display